Open frame power supply and their application

Open frame power supply units are AC/DC switch-mode power supply units that have been built as printed circuit board (PCB) components without housing for installation into other devices.

The 18W to 450W power range offers standard sizes of 3”x2”, 4”x2”, and 5”x3” to ensure easy installation into the end application.

The following criteria must be taken into account when selecting the right open frame power supply unit: the application range and the power data, the protection class, the electromagnetic compatibility (EMC), and the installation location.

Application range

The safety structure of the power supply unit varies depending on the application range. Power supply units for medical applications (60601-1) must withstand stricter requirements compared with industrial power supply units (60950-1), whereas other requirements apply for household devices (60335-1). The clearance and creepage distances in particular vary in accordance with the safety standards to be adhered to. Depending on the country where the device will be used, there are 100V-240V wide-range power supply units or 115V-230V single range power supply units. Tolerances must also be taken into consideration here as many power supply units do not provide the same output at low input voltages as they do at high input voltages. This is known as voltage derating. The efficiency guidelines stipulate various requirements for electrical devices, including compliance with efficiency classes A++ to G. A higher rating is easier to achieve for power supply units with a high efficiency level (94% at 120W) and low standby power consumption (<210mW).

Protection class

Protection class I devices must have a protective conductor to protect users from electric shocks, also in the event of a fault. This protection class is often applied to devices with metal housing as the assembly does not provide for any additional insulation. In a fault situation, the current flows through the protective conductor. Protection class II power supply units are safer than class I power supply units because they have double insulation. They also provide protection from electric shock in a fault situation without activating the fuse, RCD (residual-current circuit-breaker), or FI (ground fault circuit interrupter).

Electromagnetic compatibility (EMC)

An open frame power supply unit as a standalone assembly does not need to meet any EMC guideline specifications. This is why many devices with built-in power supply units need to have another filter to be EMC-compliant. Good-quality power supply units sustain the EMC thresholds even without insulating metal housing, filter or ferrite on the wiring. The harmonics also need to be taken into account, which are generated by switch-mode power supply units, along with the output factor. Devices with an input power of less than 75W must have a power factor correction (PFC), which is often omitted in the case of particularly inexpensive switch-mode power supply units. If a PFC is needed, the device manufacturer must initiate the necessary measures to ensure compliance with the EMC thresholds.

Installation location

Cooling

There are three ways to manage the temperature. Convection cooling involves cooling without fans. The advantage of this is that openings are often not required in the housing and there are no noise emissions. If the open frame assembly is bolted onto an aluminum profile for heat conduction, this is known as conduction cooling. This method of cooling requires special attention to be given to the surface temperature of the accessible parts. The power range of many power supply units can also be considerably extended through active cooling using a fan (forced cooling, or FC), depending on the air flow supplied.

Installation position

The installation position of the power supply unit plays an important role in temperature management. Not all power supply units can be used in all installation positions and overhead installation is often excluded. In addition, an awkward installation position can also result in premature output derating.

Operating and ambient temperature type

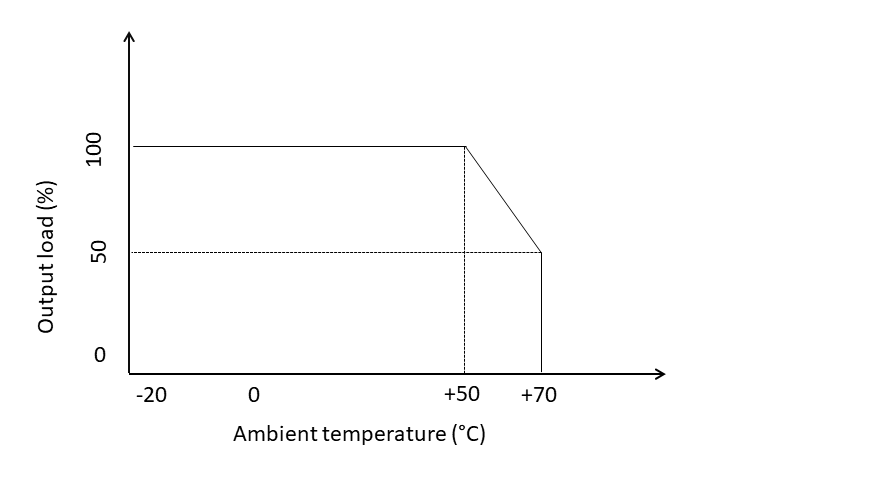

Typical temperature ranges in which switch-mode power supply units deliver their full output power are between -20°C and 50°C. Beyond that range, the rated power is often derated to 50%.

Operating height and air pressure

The operating height and the air pressure have an impact on the insulating clearance distance. As the height increases, both the air pressure and the insulating effect of the air decrease. The distances between the air gaps therefore need to be increased for power supply units that are intended for use at tall heights. Standard operating heights are 2000m for IT/household devices, 3000m for medical devices, and 5000m for special devices.

In addition to our built-in power supply components for industry, FRIWO also offers open frame power supplies with medical approval.